Excerpt

Source: Journal of Animal Physiology and Animal Nutrition

By: Muhammad Tegar K.K.

INTRODUCTION

Background

Sheep are one of the livestock animals bred for meat production. In many developing countries (including India), around 40% of sheep are slaughtered as culls. Livestock farmers in developing countries, including India, often neglect the Body Condition Score (BCS), resulting in poor-quality sheep and limited meat production. Improvements can be made by providing concentrate feed for 90 days to enhance carcass composition and meat quality for consumer acceptance. However, high costs and significant fat content pose challenges.

To address this, previous research focused on reducing feed duration or adding non-protein nitrogen (NPN) and rumen-protected fat. These studies used high levels of concentrate, leading to excessive fat and poor feed conversion. Thus, these approaches are inefficient for feeding. Fat accumulation affects meat quality, from changes in taste and color to higher levels of omega-6 fatty acids compared to omega-3. Excessive concentrate feeding also increases the risk of bloat, acidosis, and laminitis. An alternative solution is complete feed with high fiber forage and balanced concentrate suitable for sheep's digestive system.

Objective

This study aims to determine the effect of providing complete feed to improve BCS, carcass traits, and the number of carcasses in cull sheep before slaughter.

Materials and Methods

Materials

The research was conducted at the Central Sheep and Wool Research Institute, India. A total of 41 cull sheep were used, with an average age of over 6 years and a weight of 31.4 kg. Five sheep were slaughtered on day 0 to assess carcass characteristics. The remaining 36 sheep were randomly divided into 3 groups of 12 each and individually and intensively maintained. Sheep were allowed to graze from 6:00 AM to 8:00 AM and 5:00 PM to 7:00 PM.

Feeding and Live Weight Recording

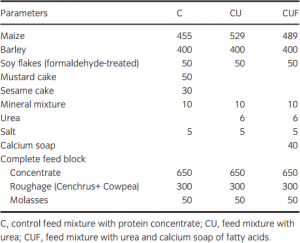

Feed was provided ad libitum in the form of Complete Feed Blocks (CFB), composed of 65% concentrate, 30% straw, and 5% molasses. CFB was created by mixing urea and molasses first, then evenly spraying onto concentrate and straw before thoroughly mixing using a horizontal mixer. The mixture was then pressed at 5000 psi (351.5 kg/cm2) using a CFB pressing machine.

Table 1. Composition of CFB in 3 different treatments